YB

Black Metallurgical Industry Standard of the PRC

YB/T 4073—2007

Replace YB/ T 4073— 1991

5. experiment method

5.1 Test block preparation

5.1.1 Prepare 3 separated test bars and rods per package (induction electric furnace times) of molten iron, according to the provisions of GB/T1348, GB/T9439.

5.1.2 The preparation of the cast test lugs shall be carried out according to the provisions of GB/T1348 and GB/T9439. The specific position of the test lugs shall be determined by both parties.

5.1.3 The chemical composition shall be sampled and tested batch by batch, and shall be carried out in accordance with the relevant standards of GB/T223.

5.1.4 The metallographic examination and mechanical properties of the specimens and castings are tested under the same conditions.

5.2 Mechanical performance test

5.2.1 The shape and size of the tensile specimens is prepared according to the provisions of GB/T1348, GB/T9439 and JB/T7945.

5.2.2 The tensile test is carried out in accordance with the provisions of GB/T228.

5.2.3 The impact test is carried out in accordance with the GB/T229 standard.

5.2.4 The hardness test is carried out in accordance with the provisions of GB/T231.1 standard.

5.3 The metallographic examination is carried out in accordance with the provisions of GB/T 9441 and GB/T 7216 standard.

5.4 The combination of the cooling water pipes and the cooling staves’ body and the anti-carburizing effect of the cooling water pipes is based on the test results of the single-cast test block. The inspection method is shown in Appendix A.

5.5 The appearance of the cooling staves is visually inspected.

5.6 The inspection of the dimensions of the cooling staves shall be measured piece by piece with a profile gauge and other suitable measuring tools.

6. Inspection rules

6.1 The inspection of the cooling staves is inspected and accepted by the supplier’s inspection department.

6.2 The final inspection is carried out at the supplier.

6.3 When both the supplier and buyer dispute the quality of the castings, the inspection may be conducted by a third party agreed upon by both parties.

6.4 Batch: The cooling stave poured by the same package of molten iron is a batch.

6.5 Evaluation and retest of test results.

6.5.1 When testing the tensile strength, first test a sample. If the result meets the requirements, the batch is qualified. If the test result does not meet the requirements and is not caused by the reasons listed in 6.5.3, two other samples can be taken from the same batch for retesting.

6.5.2 If the re-inspection results all meet the requirements, the batch of the castings is qualified. If one of the retest results does not meet the requirements, the batch is not qualified.

6.5.3 If the test result doesn’t meet the requirements due to one of the following conditions, the test is invalid. At this time, the test shall be re-tested according to 6.5.1 and 6.5.2.

a) Improper loading of the sample on the test machines or improper operation of the test machines;

b)The sample has casting defects or improper cutting;

c) The sample is broken outside the gauge length;

d) There are casting defects on the fracture of the sample.

6.6 The mechanical properties of the ductile cast iron cooling staves are based on the tensile strength and elongation. The mechanical properties of the gray cast iron cooling staves are based on the tensile strength.

6.7 The ball passing and water pressure test of the stave coolers shall comply with the provisions of 4.11 and 4.12 as the basis for acceptance.

6.8 The anti-carburizing test of the cooling staves shall comply with the provisions of Appendix A as the basis for acceptance.

6.9 The results of the metallographic examination of the cooling staves are only used as a reference for the quality assessment of the manufacturing, and are not used as the basis for acceptance.

3. Package, mark, transportation and quality certificate

7.1 package

7.1.1 Use package that ensures the cooling staves’ body, the water pipes and brick-paneling are not damaged.

7.1.2 The brisk-inlaid stave coolers should be packaged waterproof and rainproof.

7.1.3 The inlet and outlet of the water pipes of cooling staves shall be protected by covers. Water and foreign matter is not allowed to enter. The exposed parts (protective casing and water pipes) should be coated with anti-rust paint.

7.2 mark

The stave coolers should be cast with the factory label or trademark, section (band) number, part number and casting number.

7.3 transportation

7.3.1 When the cooling staves are hoisted, anti-collision measures should be taken to protect the pipe heads and the bricks.

7.3.2 The cooling staves are usually transported in bare form, when transported by cars can be without package. The train transportation should be properly packaged. The nozzle collision should be avoided and the bricks should be protected.

7.4 Quality certificate

7.4.1 The qualified products shall be issued a certificate by the quality department of the factory.

7.4.2 The certificate should include the following content:

a) Product model;

b) Product name;

c) Contract No;

d) Product number;

e) Manufacturing plant;

f) Manufacturing date.

7.4.3 When the cooling staves are shipped from the factory, the supplier’s quality inspection department shall provide the test records for the quality indicators and product certification certificates of the cooling staves.

Appendix A

(normative appendix)

Anti-carburizing test of cooling water pipes

A.1 The anti- carburizing test shall take the separated anti- carburizing test bar as the acceptance basis, and the inspection should be carried out before mass production, and the mass production can only be carried out after qualified.

A.2 Methods and technical requirements of anti-carburizing test:

a) The eutectoid layer and free cementite structure are not allowed on the surface of the test steel pipes;

b) Sampling and analysis from the steel pipes’ surface to a depth of 1 mm, the average carbon addition amount of the relative matrix is ≤11%;

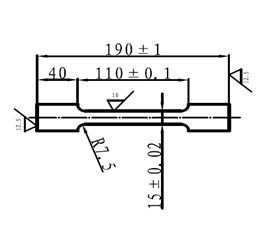

c) Steel tube tensile test (see Table A.1);

d)There is no fuse between the steel pipe and the cast iron body, and the gap is ≤0.3mm.

Table A.1

|

Steel number |

Rm N/ mm2 |

A % |

|

10 |

≥340 |

≥24 |

|

20 |

≥390 |

≥20 |

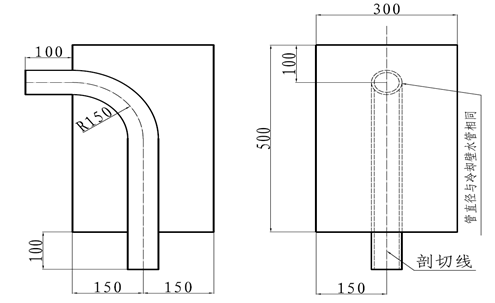

A.3 The shape and size of the anti-carburizing test blocks shall comply with the requirements of Figure A.1.

Figure A.1 Shape and size of the anti-carburization test blocks

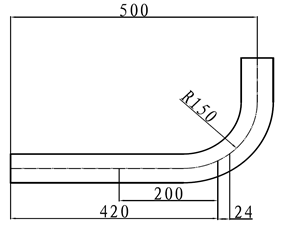

A.4 After casting, the test piece is processed by cold working to the position of the cut line on the figure, and the steel pipe in the half piece is knocked down for mechanical properties and metallographic examination. The sampling method is shown in Figure A.2.

a) Take one sample in each of the bent and straight sections of the steel tubes for metallographic analysis;

b) Take a mechanical property sample at a portion of size 200

Figure A.2 Schematic diagram of the sampling method

Appendix B

(informative appendix)

Cooling stave anatomical test

B.1 The cooling staves of the anatomy are SE*LECTED jointly by the supply side and the demand side.

B.2 Anatomy is carried out in both vertical and horizontal centers’ directions.

B.3 Measure the position of the cooling water pipes on the anatomy section, and its offset must not exceed ±15mm.

B.4 The test of the metallographic organization and the mechanical properties should conform to Table B.1.

B.5 The quality requirements for the anti-carburization test of the steel pipes on the section are carried out according to Appendix A.

Table B.1

|

Anatomy sampling location |

Spheroidization grade |

Base tissue |

|

1/2 of cooling staves’ thickness |

Levels 3 to 5 |

Ferrite amount≥80% |

Welcome 2026!

Welcome 2026!

Merry Christmas!

Merry Christmas!

Continuous Learning, Lasting Professionalism

Continuous Learning, Lasting Professionalism

Another Successful Shipment of Chequer Support to Canada | A Testament to Quality and Confidence

Another Successful Shipment of Chequer Support to Canada | A Testament to Quality and Confidence